Device Assembly

Customization and automation

Device Assembly

Customization and automation

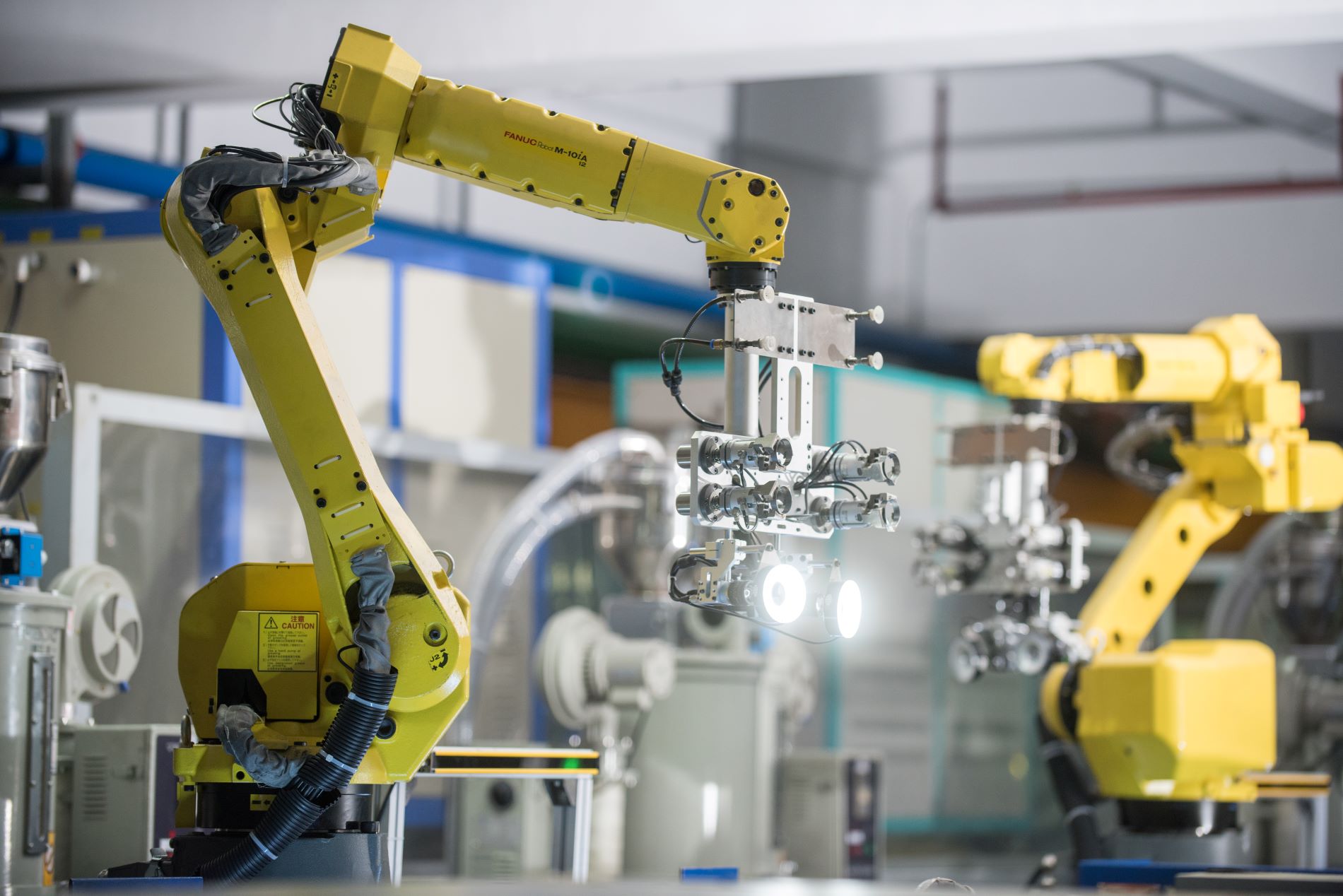

Assembly is where it all comes together. We perform over 180 million device assemblies every year. These include printed circuit boards (PCB), electronic sensing devices, metal fabrication, sonic, laser and hot-plate welding, and advanced surface decoration.

To shorten lead times, ensure Design for Manufacturing and Assembly (DFMA) and maintain quality control, we have invested in advanced assembly technologies and control systems. These include line balancing, automation assembly lines, a real-time operating system, a flexible manufacturing system, lean manufacturing, and just-in-time deliveries (JIT).

Assembly runs smoothly due to a strong foundation of automated assembly technologies and comprehensive worker training programs.

Our automated assembly machinery includes:

- Auto assembly line for kids’ power toothbrushes

- Auto assembly line for adults’ power toothbrushes

- Auto assembly line for toothbrush heads

- Auto household-brush tufting/trimming/labeling/handle assembly machine

- Auto soldering machine

We put our products through inline function testing to make sure the core features work as they should.

Inline function testers include:

- Current tester

- Air leakage tester

- Check valve tester

- Finished good function tester

- Button force tester

- Hot stamp height tester

Auto household-brush tufting/trimming/labeling/handle assembly machine

Finished goods function tester

Speak to an Expert

Speak to an Expert